One of the mandates of Guru Angad Dev Veterinary and Animal Sciences University, Ludhiana is to uplift the livestock sector in the state of Punjab with latest scientific practices through education and skill training of the unemployed youth, farmers and women about profitable livestock farming viz. Dairy, Poultry, Piggery, Goatry, Fisheries etc. The state government is also putting great efforts in diversifying agriculture. One such effort is to commercialize dairying in the state. This has been examplified by Sh. Ranjit Singh Rohlen who has adopted dairy farming as a business.

Sh. Ranjit Singh Rohlen was born on Feb 15, 1964 in the village Rohlen of Ludhiana district of Punjab. This village is situated near Samrala on Chandigarh-Ludhiana National Highway. He obtained his primary education from the village school itself. His father, Sh. Baldev Singh was himself a farmer. He had great influence on the mind of this growing child. Ranjit Singh, at a very young age, developed a special bonding with the animals (buffaloes, in fact) reared in the family. He made up his mind to adopt dairy farming as his career and he commenced the initial activities in the year 1995. He owned 35 buffaloes at that time. Each buffalo yielded on an average 13-14 litre of milk daily with a maximum output of 18 litres. He used to sell this milk to a local middleman at the rate of Rs 20 per litre. Common fodders prevailing in the area were grown at the farm itself and fed to animals ad lib along with a bucketful of concentrate ration. A traditional shed (Fig. 1) with pucca flooring had been constructed for the comfort of these buffaloes. Two labourers were employed to look after these animals.

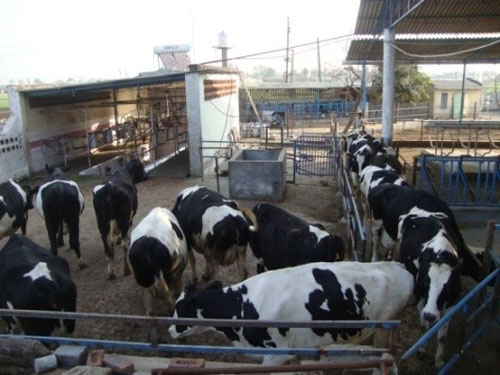

Sh. Ranjit Singh consulted fellow dairy farmers and changed his operational system to mixed farming in the year 2000. He added 20 cow heifers of Holstein Friesian Cross pedigree to his existing herd. He purchased these heifers from Haibowal Dairy Complex, Ludhiana at a price tag of Rs 1500 per animal. Loose housing system was adopted and a new shed (Fig. 2) was constructed for these animals. The heifers started calving one and a half years later. The higher milk production of these cow heifers (in comparison to buffaloes) prompted him to purchase a few more adult cows. He, then, added 10 more HF Cross cows in the year 2003.

During winter months, the buffaloes were tethered alongside a manger that was constructed in the open. The summers are very hot in Punjab. To avoid summer stress, all the animals (buffaloes and cows) were allowed to wallow in a water tank during hotter part of the day. A pucca wallowing tank (Fig. 3) was constructed in the premises of the farm with dimensions of 30¢´30¢ and six feet deep. A ramp had also been constructed for the animals to enter into this wallowing tank. Water was added to the tank continuously from a tube well and it was taken out from the other side to the rice fields through specially constructed closed water channels. The continuous drainage of water from the wallowing tank helped to keep it clean at all times.

When only buffaloes were used to be reared, maize was the major fodder crop of kharif season and berseem of Rabi season. With change in rearing system (i.e. mixed farming), a change in fodder production system was also imminent. Kharif season witnessed cultivation of cow-pea (legume) along with maize (non-legume). Similarly, earseem (a legume) along with oats and rye grass (non-legumes) became the major fodder crops of rabi season.

The labourers used to harvest the fodder manually when the number of animals was quite less i.e. when only buffaloes were reared. The demand of fodder skyrocketed with the addition of cow heifers. The labourers started showing reluctance to harvesting increased quantity of fodders. This led to the initiation of mechanization at the farm. A fodder harvester was purchased from Moga. This harvester was powered by a tractor. It led to saving of lot of time and manpower.

In coming years, Mr. Ranjit Singh had to face new challenges in the form of increased incidence of Infertility and Mastitis in cows. To improve his latest technical know-how, he got himself admitted in a training course, “Specialized Dairy Farming” from Guru Angad Dev Veterinary and Animal Sciences University, Ludhiana in the year 2008. After getting training, he altogether changed the scenario of his dairy farm. He sold all the buffaloes. All the old structures at the farm including the wallowing tank were dismantled. He made his mind to start a new venture in dairy farming with HF cows only.

A new modern shed was constructed for the cows with all the technical inputs coming from University experts. Its dimensions were 120¢´80¢. It could easily accommodate about 100 cows at one time. A milking parlour was also eructed at the premises with a very low cost. An amount of Rs 7.00 lakh was spent on this structure. It was fabricated by using only locally available material and know-how. A total of eight cows (4 in two rows) can be milked at one time. A holding area was also provided for the cows that are to enter into the milking parlour. This practice greatly improved the quality of milk.

To cope up with the shortage of labour, silage making was started at the farm. Four silo-pits rather bunkers were specially constructed at the farm. All these silo-bunkers were constructed above the ground level so as to prevent flooding by rain water. An amount of Rs 18.00 lakh was spent on the construction of shed, milking parlour and silo-bunkers.

Rainy season used to bring lot of miseries at the farm. The animals have to stroll through mud. For the comfort of the animals, individual cubicles were installed at the farm in 2013. Each cubicle measures 6’x4′ These cubicles were made on a raised platform with mattress type bedding. The flooring remains dry throughout the year. This made the animal to lie down on the mattress for most part of the day. Each animal enjoys rumination and produces milk to her capacity.

Specially designed foggers have been installed in the shed to keep the internal environment cool during hot summer months of May-June. The hot humid conditions of July-August are taken care of through big fans fitted on the pillars.

There are a total of 100 animals at the farm with a ratio of 60:40 for adults and heifers. Out of 60 adult animals, 50 are in milk. The average daily milk yield is around 35 litres per animal. The maximum milk obtained from an individual cow at the farm was 52 litres in a single day. Milk is sold to Verka Cooperative Society at the village level. It fetches on an average Rs 36 per litre. Around 25 animals are sold to various customers each year. Each cow usually fetched Rs 80,000. The male calves of high producing dams also provided very good returns. These were often sold to Semen Bank, Lucknow and progressive farmers of Haryana state. There is compartmentalization at the farm. Animals are reared in groups according to their growth status and production level.

The concentrate ration is customized according to the production level of the animals. Technical help is taken from the concerned scientists of GADVASU for the preparation of this concentrate ration. Around 150 quintals of ration is prepared during each lot. It costs around Rs 26 per kg. Around seven quintals of concentrate ration is usually consumed each day. Individual fresh cow often receives 10 kg ration while late calvers receive 6 kg share. The concentrate ration is often mixed with silage and then, fed to animals in the manger.

Cows are exclusively bred artificially and the farmer himself is trained enough to perform Artificial Insemination (AI) at the farm. He has obtained special training of AI from Dairy Development Department’s Extension Centre, Bija. Semen is procured from Verka Milk Cooperative Society and from private agencies. The animals are examined by the farmer himself for pregnancy status usually three months after doing AI. The pregnant animals are mandatorily dried off two months before the expected date of calving. Certain health problems like mastitis and repeat breeding are usually experienced at the farm. Mastitis occurs in about two percent cows while repeat breeding problem is faced in four per cent animals. The problematic animals are treated at the farm itself after following professional advice from university experts.

The calves are reared in individual pens which have been constructed on a raised platform to avoid flooding during monsoon season. The calves are weaned off from the very first day. The colostrum is usually offered to them in pails. They are usually fed milk and grower feed as per university recommendations. Milk is, often, withdrawn when they attain the age of four months. Naval disinfection, horn disbudding, regular deworming etc. is followed very sacredly. Cleanliness is followed rigorously. In spite of all these procedures, around four per cent calves do suffer from diarrhea (enteritis) and a few of them failed to cope up the medical treatment especially in winter.

Owing to his hard work, Mr. Ranjit Singh got more than 100 prizes from recognized institutes like Guru Angad Dev Veterinary and Animal Sciences University, Ludhiana, State Animal Husbandry Department, Milk Cooperative Federation and Private Agencies. The important prizes include ‘First Prize at National Livestock Championship at Shri Mukatsar in 2014’ and ‘Chief Minister Award in dairy farming (Cattle) category from GADVASU in 2015’.

GADVASU, Ludhiana organizes specialized training course for dairy farmers mostly during the months of January, May and July each year and also during other months. The trainees of this course are usually taken to Rohlen to showcase the latest technologies adopted at the farm of Mr. R S Rohlen. The trainees got motivated after seeing the success of this farmer and 42 trainees started commercial dairy units of their own in Ludhiana district itself. In this way, the scientific practices recommended by GADVASU, Ludhiana are being spread to other farmers through ‘organized visits to his farm’.Vet Varsity has also prepared Android Mobile Apps- “Dairy Farming” and “Reproduction Management of Dairy Animals” downladable from Google Play Store, besides, university has various other programmes for the livestock farmers. Dr A K Singh, DDG (Agri. Extn) ICAR, New Delhi visited his farm on Nov 18, 2015. He appreciated the management as well as various comfortable environments provided to the dairy cows, being the key for his success.

We pray to God that this hard working and honest farmer get success at every step and will act as lighthouse for other budding dairy farmers of the state. Amen!!

Be the first to comment