Microbial spoilage of eggs

Introduction

Under healthy breeding conditions, the egg content is sterile. However, the eggshell surface can be contaminated by a diversified microflora. In order to cause spoilage of shell of egg, microorganisms must contaminate the shell, penetrate through the pores in shell and inner membrane, reach the egg white and yolk and grow there. The microbial contamination can lead to spoilage problems.

Bacterial spoilage of eggs

- Bacteria are more common spoilage organism.

- Bacteria cause rots in egg.

- When bacteria grow within the egg, they decompose the content and form byproduct.

- The microflora of the eggshell is dominated by Gram-positive bacteria such as Staphylococcus, Streptococcus, Aerococcus and micrococcus.

- Other minor contaminants are Gram-negative bacteria, such as Salmonella, Escherichia (De Reu et al., 2009; De Reu et al., 2008; Moats, 1980).

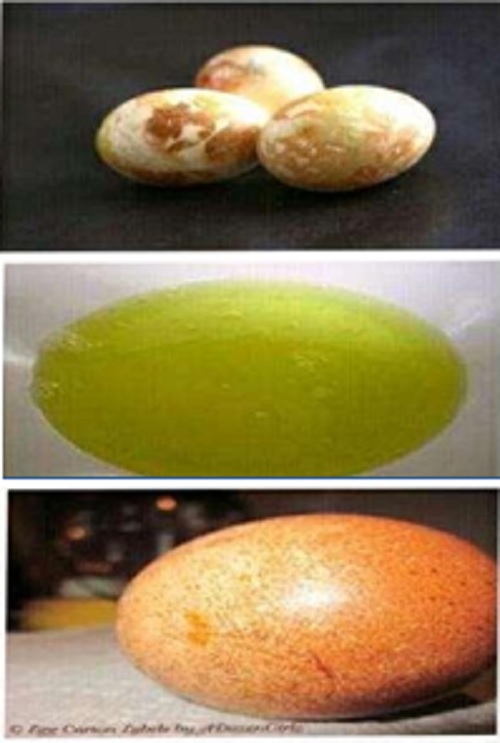

1. Green rot

- It is caused by Pseudomonas fluorescence.

- Green egg white shows fluorescence when exposed to UV light

- In later stage of spoilage, egg yolk disintegrates and mask green color of egg white.

- Odor is lacking or fruity or sweetish.

2. Colorless rot

It may be caused by Pseudomonas, Acetobacter, Acinatobacter and coliform.

3. Black rot

- It is caused by Proteus and sometimes Pseudomonas and aeromonas

- Egg yolk blackens and then breakdown to give whole egg content muddy brown

- Odor is putrified due to H2S

4. Pink rot

- It is caused by Pseudomonas usually at the later stage of green rot.

- They are similar to colorless rot except that pink coloration occurs in yolk and white.

5. Red rot

- Most infrequently occurring one.

- Caused by a species of serratia.

- Odour is mild & not offensive.

Fungal spoilage of Egg

- Molds causing spoilage of egg includes –Penicillium, Sporotrichum, Mucor, Botrytis, Alternaria, Thamnidium etc.

- Spoilage of eggs by fungi goes through stages of mold growth.

- Pin spot molding.

- Fungal rotting.

1. Pin spot molding

In this case, small compact colonies of mold appear on the shell and usually just inside the shell.

2. Fungal rotting

- It is the final stage of spoilage by mold.

- In this case, mycelium of the mold grows through the pores and cracks in the shell

- Jellying of egg white may occur and colored spots may be produced

- Hypha of mold grows through the yolk membrane and rupture it, so that yolk mixes with the white.

Monitoring and reducing the spoilage of egg

- Various techniques have been explored for the reduction of the level of eggshell contamination and enhancing the natural defenses of the egg itself.

They include both the:

- Upstream step –This includes hen selection, improvement of the practices of breeding and farm management.

- Downstream steps – This includes packaging, transport and storage of eggs.

- The microflora and also the number of cracked or broken eggs, are related to the type of hen housing systems.

- The design of conventional cages was optimized for achieving high hen performance with the additional advantage of hygienic egg quality.

- Therefore, attention should be paid in designing cages ensuring the best egg hygiene quality.

- The practices of egg collection on the farm, as well as the sorting, packaging, storage and delivery, must also be improved to reduce contamination

- Cross-contamination must be avoided by preventing contamination of the staff and the environment.

- Attention should be paid in improving egg storage conditions, including temperature and duration conditions.

- The storage of eggs at refrigeration temperatures is an effective way of reducing the liquefaction of egg white, the loss of integrity of the vitelline membrane, and consequently, the bacterial growth.

- In the packaging centres, egg candling is a key step for controlling the microbiological quality of eggs.

- The use of UV light has been particularly efficient in detecting the fluorescent pigment due to the spoilage of the albumen by Pseudomonas (Elliot, 1958)

- In the egg product industry, the destruction of microorganisms is mainly carried out by heat treatments at temperatures around 65 to 68°C for 5 to 6 min for both whole egg and egg yolk.

- The treatments are milder for egg white (around 55 to 57°C for 2 to 5 min), due to the higher thermal sensitivity of egg white proteins.

- Practices of freezing and drying are efficient measures which reduce spoilage.

- The use of peracetic acid in solution with hydrogen peroxide and acetic acid on the shell eggs .

- The methods used to predict spoilage events during egg product processing, can be divided into two groups:

- Those targeting bacteria and those targeting markers of spoilage (end product compounds coming from the bacterial metabolism).

- Alternative methods, based on molecular tools such as PCR, have been developed, which identify spore-forming bacteria among the broad range of whole egg flora. (Postollec et al.,2010).

- Other alternative approaches use optical methods (red LED light) for studying the growth of spoilage bacteria involved in the spoilage of egg products (Riva et al., 2001; Correa et al., 2008).

Preservation of eggs from spoilage

- Eggs have several ways of protecting itself from microbial spoilage. Shell and underlying membrane serve as first line of defence to prevent entry of microorganisms. In addition to physical barrier, egg albumin is not suitable growth medium and discourage growth of many microorganisms.

- Characteristics of egg albumin that discourage microbial growth include pH of 9-10, low level of simple nitrogenous compound, apoprotein that binds riboflavin, avidin that binds biotin, ovo-transferrin that chelate iron, and lysozyme that hydrolyze peptidoglycan of bacteria.

- Despite physical barrier and other anti-microbial factors, many microorganisms can invade and cause spoilage of egg.

Therefore, following methods are employed for its preservation:

i. Asepsis

- Great care should be taken to reduce contamination by fecal matter by dust and nest.

- When eggs are broken for freezing or drying, spoiled egg should be discarded and contamination from equipment can be reduced by sanitizing it.

ii. Removal of microorganism

- Various methods can be employed to remove dirt and faecal matter from egg shell.

- Dry cleaning by sand blasting removes dirt and bloom.

- Washing with warm water removes dirt, bloom and apart of microorganisms but encourage penetration of bacteria into egg through pores in shell.

- Use of disinfectant in washing water reduce number of microorganism.

iii. Use of heat

- Heat treatment suggested include heating whole egg in oil for 10 minutes at 600C or in water at 54.4oC for 80 min, Immersion of egg in boiling water for few second, immersion of egg in hot detergent, Sanitizer solution at 43.3oC to 4oC.

- Pasteurization is required for most egg product because of heat coagulability of egg, stabilization is required before pasteurization.

- This includes addition of aluminum salt and adjustment of pH.

iv. Preservation by low temperature

Chilling

- Eggs are commercially stored for six month or longer, at a temperature of -1.7oC to – 0.55oC and relative humidity of 70-80%.

- If temperature is greater than -1.67, there is more rapid penetration of microorganisms and growth into egg and more physical and chemical changes.

- Special treatment like impregnation of egg shell with colorless and odourless mineral oil keeps out moisture, slows dessication and air penetration during chilling.

Freezing

- Eggs are first washed with 200-500ppm chloride solution and broken.

- Egg yolk and egg white are separated and they are frozen separately at -17.8oC to – 20.5o

v. Preservation by drying

- Eggs are first washed with chloride solution, broken and then yolk and white are separated.

- Liquid egg is then dried by drum drying or spray drying method.

- Glucose should be removed from egg before drying because it causes browning of egg.

vi. Preservation by chemical preservative

- Preservatives may be used on shells of egg in the atmosphere around them and on containers for egg.

Some of them are:

- Waxing and oiling of shell keep the shell dry, reduce penetration of oxygen into the egg and reduce passage of carbon dioxide and moisture out.

- Immersion of whole egg in solution of sodium silicate is also a good preservative.

- Use of CO2 in ozone in storage atmosphere improves quality of egg.

Be the first to comment