Now-a-days, the sustainable production of consumer products is the major challenge faced by modern societies and future generations, after decades of reliance on fossil resources which, on one hand, did generate economic growth and prosperity but, on the other hand, has left serious ecological, geopolitical and social legacies. In this alarming context, the concept of circular bioeconomy is developing and promotes as a new sustainable and knowledge-based economic model centered on the use of renewable biomass/waste-derived agro-industrial and municipal wastes. What happens when an industry’s by-product turns out to be as precious as its primary products?

In this regard, every year millions of tons of chicken feather wastes gather in the waste stream. But, traditional disposal strategies such as incineration, burial in landfills are expensive, difficult and generate greenhouse gases or pose danger to the environment. In spite of advances in the biomedical field, there are no ideal keratin-based biomaterials (biocomposite) available for clinical use till date, but their unique properties, such as remarkable biocompatibility, propensity for self-assembly, biodegradability, mechanical strength and natural profusion, make them good raw materials for future applications. Although there is scope for better utilization of the keratin-based wastes, at present there are no sustainable strategies developed for making good use of these wastes. Making good use of wastes from renewable resources is an attractive concept from both commercial and environmental perspectives is a challenging task. If animal wastes can be reused, we can turn the waste into wealth. Keratin based wastes can be recycled made eco-friendly in many ways in order to ensure sustainable practices in livestock/ poultry farming and reduce environmental threats.

Feathers are made up of 90% keratin – the same fibrous protein that gives hair, hoofs, and horns their toughness. Researchers are exploring novel methods for turning the poultry industry’s feather wastes into products ranging from paper to automobile body parts to high-quality animal feed, saving trees and replacing fossil based/man-made materials. In this regard, we have initiated to develop a proof of concept to exploit the potential to convert feather wastes into useful consumer products. The present need is to find the green and eco-friendly methods for the extraction of keratin biomass with the minimal usage of harmful acids and chemicals. The use of keratin biomass for biomedical applications is one of the areas of research, still needs to be explored. There is no systematic study on morphological aspects of keratin-based wastes such as hoof, feather, and wool which have potential biomedical applications.

Chicken feather waste, which is generated almost all over the world in large quantity, is currently, classically incinerated or ends up in landfill or as low-grade animal feed. But it has the potential to be a valuable resource as keratin.

Circular economy

The people believe that demand for products from the circular economy – where by-products from one industry are used as the raw materials from another – could benefit from a phenomenon known as conscious consumerism.

Strong bioplastics

Most of the waste is a money-making material. Due to its high keratin content, feathers are likely to produce bioplastics that are stronger and more tear-resistant compared to those using modified starch or plant proteins for example. We are looking at how to transform unwanted feathers into biodegradable plastics; however, there were challenges ahead in using feathers as raw material.

Safe to handle

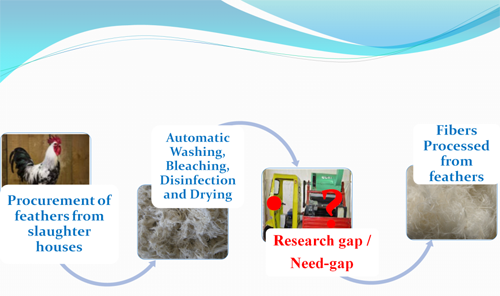

First, the feathers need to be sanitized before processing to remove any pathogens. Since feathers are also very light, it can be hard to get them to flow through machines. We have figured out how to pre-treat feathers so that they are cleaned and safe to handle, and how to turn them into raw material.

Feather-based raw materials

The interdisciplinary team from Veterinary College, KVAFSU, Shivamogga (Karnataka) has created samples of feather-based materials that could be used for packaging, using a process where heated material is injected into a mold to shape it. Our next challenge is to scale up their production process for industrial manufacturing and test how best feather-based raw materials work in particular end products. At present, we are looking at how to make food packaging materials from feathers, and also developing other applications such as slow-release fertilizers, composite materials, and flame-retardant coatings, depending on economic and technical feasibility.

Morphology of Feather

The surface morphological studies of feather and wool showed rough surface due to the presence of hooks and the cuticle cells respectively which played an important role in interfacial adhesion and mechanical bonding in biocomposites. The biocomposites were prepared using starch-based bio resin, chitosan and then reinforced with short and long keratin biofibres. Scanning electron micrographs of fractured surfaces of biocomposite showed good dispersion of matrix by short fibres when compared to long fibres. The chicken feather was made up of the three parts; a central axis called rachis/shaft, the secondary structures (the barbs that are attached to the rachis and the third structure (barbules) which were connected to the barbs. The barbs at one end of the feather were firm, compact, closely knit, while those at the other end are downy, i.e. soft, loose and fluffy. The down feather provides insulation, while the flight feather provides an airfoil, protects the body from moisture the skin from injury and provides colors for displays.

Production of keratin based biofiber from feather waste

In spite of wider anticipated applications of keratin waste, due to lack of processing methods, we currently have a limited ability to utilize them for different applications. Therefore, the present study was proposed to optimize the process to produce clean fibre from chicken feather and wool wastes, which serve as a basic biomaterial for the production of various biobased products such as biocomposites, bioinsoles, for multiple biomedical applications. For the competitive poultry industry, the challenge is to turn the poultry feathers into valuable new products that add to the company’s bottom line. Though there has been significant controversy in recent years over the human health effects of poultry wastes, especially used litter and processing plant wastewater that ends up in waterways, chicken feathers are relatively clean and do not generally pose a health risk. Contamination of feathers with chicken blood and feces can present a problem, but in general, feathers are continuously removed from the processing area to make room for new feathers as more chickens are processed.

After washing in regular tap water, feathers had their barbs fanned out, but a significant odour remained. Water holding in the feather turned it black after a few days due to bacterial decomposition, which may be due to pathogenic bacteria such as Enterobacter, Escherichia, and Salmonella. The use of disinfectant was necessary during the processing of feathers. Chemical Treatment helped to remove moisture content from the fibers thereby improving the strength of the materials. The size of dried keratin materials was reduced using domestic mixer within closed jar for 5 min., fluffed the feather into a suitable biofibres. Morphological studies revealed that the fiber surface was not damaged by this method. Fibre product consisted of barbs with intact barbules and thin rachis with barbs sheared off. Composites differed in the amount of fiber, fiber type, fiber length, fiber orientation, and possibly fiber hybridization. In general, short-fiber composites were used in lightly loaded or secondary structural applications, while continuous (long) fiber-reinforced composites are utilized in primary applications and are considered high-performance structural materials. From the morphological point of view, the presence of honeycomb structures makes poultry feather fibers have low density and also provides air, heat-insulating capabilities unlike any other natural or synthetic fibers. The relevant composites showed a decrease in mechanical and thermo-physical properties with increasing poultry feather products transition was clearly observed at 30 % content of fibre as reinforcing material. Therefore, the content of the biofibres as reinforcing material in the composite was limited to 30% in our study.

Development of keratin based biocomposite

The keratin-based wastes of livestock origin such as hoof, chicken feather, and sheep wool are potential sources for intermediary products such as biofibres, keratin-powder and biocomposites having multiple applications including bioinsole, larvicidal preparations, and bioscaffolds etc. Short fibre biocomposites are superior to long fibre biocomposites as they exhibited effective fibre-matrix interactions and even dispersion resulted in reduced brittleness and increased mechanical strength when compared to long fibre composites. Short fibre biocomposites are appropriate for the development of bioinsole.

BioInsole Technology

One of the world’s most under-exploited waste products – the feathers from poultry farms – is finding a smart way inside shoes, as BioInsole. Development of sustainable biocomposites / Bioinsole by converting chicken feather waste-based biomass using nanotechnology could potentially save thousands of barrels of (fossil) fuel annually. Our estimate suggests that footwear insoles made by this biocomposite can be affordably priced at Rs 150/pair as compared to existing diabetic insoles that cost Rs 1,000/pair, render odourless, and fully biodegradable. It is a green initiative process that uses readily available environment-friendly processes and materials. This has the potential to become an urban brand, as well as a rural solution to protect happy moments of the people which has an affordable techno-commercial platform to expand our reach of homes across the globe.

The Future scope for feathers

- Assessment of keratin-based materials for more molecular biochemical, biophysical and functional properties may further widen their applications in the field of medicine, surgery, and non-biomedical fields such as electronics, textiles, automobile and packaging industries.

- Specific strategies may be evolved for better utilization of keratin-based wastes to avoid environmental pollution, landfilling, global warming and solid waste management.

- As feather waste is an abundantly available and inexpensive natural resource of keratin the production of biodegradable by-products from these wastes with innovative technology will be the best way to make the good use of environmental pollutants/ landfills which have posed serious challenges to the local administration.

- Optimization of methods for up-scale processing of keratin-based livestock wastes ensures efficient utilization of solid wastes and a safe environment.

- There is an immense scope to exploit the use of biodegradable wastes as organic manure, unlike synthetic polymers. All these aspects indicated that there is a golden treasure on earth so, it has to be tapped to use these natural resources in fruitful.

- Widespread use of feather fiber in consumer materials and as a higher-quality animal feed is still in the future. Currently, composting is still the most cost-effective reuse of feathers. Disposal, composting, digesting, and recycling are gaining ground in handling poultry feathers; but the sheer volume [of feathers] produced overwhelms current processing infrastructure.

- Although BioInsole technology is still scaling up, the team expects it to catch on quickly. This is close to a win-win situation for almost everyone involved in the process. Feathers become a value-added product. If we can improve the production we’ve got now to handle tons and hundreds of tons, it will help the poultry industry and mankind also.

Be the first to comment